Nanocomposite is a multiphase solid material where one of the phases has one two or three dimensions of less than 100 nanometers or structures having nano-scale repeat distances between the different phases that make up the material. Making lightweight sensors with nanocomposites.

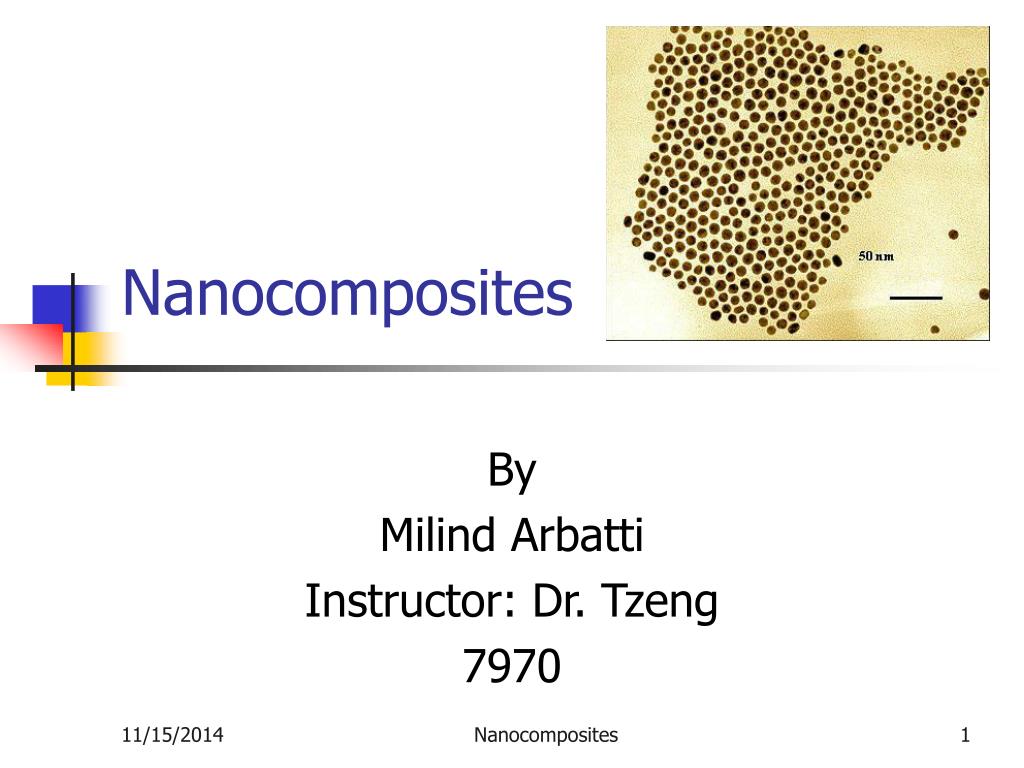

The most common example of 0D-dimensional nanomaterials is the nanoparticle.

Classification of nanocomposites ppt. Classification of nanocomposites Ceramic based nanocomposites Increase in the strength hardness and abression by refining particle size Enhance ductility touchness formability superplasticity by nanophase Change electrical conduction and magnetic properties by increasing the disordered grain boundry interface Metallic based nanocomposites Increased hardness strength. Barium-titanate with polymers InorganicOrganic Polymer nanocomposites clusters Eg. Polymer nanofiber with zero valent nanoparticles.

InorganicOrganic Hybrid Nanocomposites Nanocrystal Eg. CdS nanocrystals Poly N- vinyl carbozole- photorefractivity. About Nanocomposites Nanocomposites are a class of materials which incorporate nano-sized particles in a matrix of other materials such as polymers.

Such nano-sized particles enhance the properties of the matrix material including characteristics such as mechanical strength electrical and thermal conductivity and chemical resistance. Nanocomposites are used in a range of industries. These nanofillers may be carbon nanotubes nanoclays metal-oxide ceramics and graphene among others.

Polymer nanocomposites are gaining. Usually nanocomposites are classified as inorganic-inorganic nanocomposites inorganic matrix organic-organic nanocomposites organic filler in organic and hybrid materials ie organic in. Classification of Nanomaterials The classification of nanomaterials is based on the number of dimensions which are in nano range 100 nm.

0D nanomaterials have all the dimension within nanoscale ie. No dimension is larger than 100 nm. The most common example of 0D-dimensional nanomaterials is the nanoparticle.

Nanocomposite is a multiphase solid material where one of the phases has one two or three dimensions of less than 100 nanometers or structures having nano-scale repeat distances between the different phases that make up the material. The idea behind Nanocomposite is to use building blocks with dimensions in nanometre range to design and create new materials with unprecedented flexibility and. Nanocomposites are composites in which at least one of the phases shows dimensions in the nanometre range 1 nm 10-9 m 1.

Nanocomposite materials have emerged as suitable alternatives to overcome limitations of microcomposites and monolithics while posing preparation challenges related to the control of elemental composition and stoichiometry in the nanocluster phase. They are reported to. SciELO - Scientific Electronic Library Online.

_v1ppt 7 Nanocomposites Multiphase. 1 or more phases 100nm Properties unachievable with traditional materials Types of nanocomposites. Nano-nanocomposites Ceramic nanocomposites Metal-Nanopolymer composites Polymer nanocomposites.

In this chapter the fabrication of three types of nanocomposites based on the biocompatible electrospun hydrogels namely. I electrospun nanofiber-reinforced hydrogels ii electrospun hydrogels with biological electrospray cells and iii electrospun hydrogels with antimicrobial activity exclusively in the field of bone tissue regeneration are presented. Hydrogels have been used widely in biomaterial.

Compared to a film made with conventional composites the water drop would face more barrier going through the film made with nanocomposites because the distance between fillers is much smaller. Packaging in food medical and pharmaceutical industry. 21 Classification of nanocomposites.

Nanocomposite coating is composed of minimum two immiscible phases separated by an interface region. When the layers or grains in the nanocomposite are in nanometer range superlattice effects may further improve the properties of the coating 19. Polymer nanocomposites consist of a polymer or copolymer having nanoparticles or nanofillers dispersed in the polymer matrix.

These may be of different shape but at least one dimension must be in the range of 150 nm. These PNCs belong to the category of multi-phase systems that consume nearly 95 of plastics production. These systems require controlled mixingcompounding stabilization of the.

Nanocomposites comprise multiphase materials such as metals polymers inorganic ceramics where at least one constituent has one dimension less than 100nm. Nanocomposites are the materials of the twenty-first century having an annual growth rate of 25 due to their multifunctional. Making lightweight sensors with nanocomposites.

A polymer-nanotube nanocomposite conducts electricity. How well it conducts depends upon the spacing of the nanotubes. This property allows patches of polymer-nanotube nanocomposite to act as stress sensors on windmill blades.

When strong wind gusts bend the blades the nanocomposite will also bend. Bending changes the nanocomposite sensors. Therefore nanocomposites promise new applications in many fields such as mechanically-reinforced lightweight components non-linear optics battery cathodes and ionics nanowires sensors and.

Les nanocomposites sont une catégorie de nouveaux matériaux des composites pour lesquels au moins lun des constituants affiche des dimensions de lordre du nanomètre. Dans ce cas la matrice.