The following figures illustrate some of the important process steps of the fabrication of a CMOS inverter by a top view of the lithographic masks and a cross- sectional view of the relevant areas. The process starts with a polished silicon the substrate wafer that undergoes these steps such as Thin film growth or Deposition Doping Lithography and etching and Micromachining.

The mask that is used in each process step is shown in addition to a sample cross-section through an n-device and a pdevice.

Cmos fabrication process steps. Digital Integrated Circuits Manufacturing Process EE141 CMOS Process Walk-Through p p-epi a Base material. P substrate with p-epilayer p c After plasma etch of insulating trenches using the inverse of the active area mask p p-epi SiO 2 3 SiN 4 b After deposition of gate -oxide and sacrificial nitride acts as a buffer layer. CMOS Fabrication Steps.

Start with p-type substrate. Oxidation is a important step in IC fabrication process. SiO2 plays an important role in IC technology.

A photoresist is a light-sensitive material used in several processes such as. Start with blank wafer Build inverter from the bottom up First step will be to form the n-well. Cover wafer with protective layer of SiO2oxide Remove layer where n-well should be built Implant or diffuse n dopants into exposed wafer Strip off SiO2 826188 p substrate.

Fabrication Steps Start with blank wafer typically p-type where NMOS is created Build inverter from the bottom up First step will be to form the n-well where PMOS would reside Cover wafer with protective layer of SiO2 oxide Remove oxide layer where n-well should be built Implant or diffuse n dopants into exposed wafer to form n-well Strip off SiO2 p substrate. In this video i have explained CMOS Fabrication Process with following timecodes. 000 - VLSI Lecture Series015 - nMOS and pMOS structure on P Type Substra.

The following figures illustrate some of the important process steps of the fabrication of a CMOS inverter by a top view of the lithographic masks and a cross- sectional view of the relevant areas. The n-well CMOS process starts with a moderately doped with impurity concentration typically less than 1015 cm-3 p-type silicon substrate. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

The step by step procedure of NMOS fabrication steps include the following Step1. Processing is passed on single crystal Si of high purity on which necessary P impurities is initiated as the crystal is developed. Fabrication Steps Start with blank wafer Build inverter from the bottom up First step will be to form the n-well Cover wafer with protective layer of SiO2 oxide Remove layer where n-well should be built Implant or diffuse n dopants into exposed wafer Strip off SiO2 p.

NMOS Fabrication Steps By the process of Chemical Vapour Deposition CVD a thin layer of Si 3 N 4 is deposited on the entire wafer surface. Next the Si 3 N 4 is removed by an etchant that does not attack SiO 2. A layer of oxide about 01 micro.

MEMS Fabrication consists in the application of the following steps normally several times during the manufacturing. The process starts with a polished silicon the substrate wafer that undergoes these steps such as Thin film growth or Deposition Doping Lithography and etching and Micromachining. CMOS Fabrication Process.

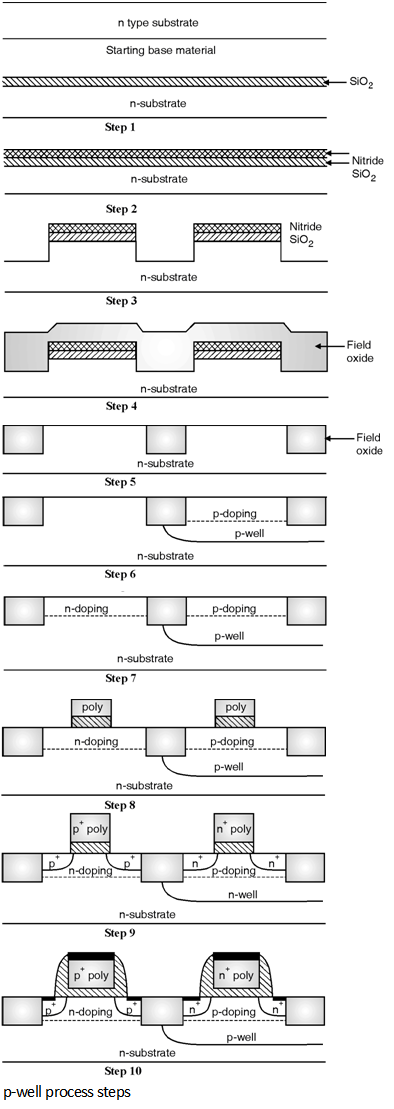

CMOS Fabrication Process p-well method Fig. 1 Pure Si single crystal Si-substrate Fig. 2 n-type impurity is lightly doped - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -.

Fabrication steps for nMOS processes The n-wells are created in the p-type substrate. The typical processing steps for the fabrication of CMOS devices may be summarized as below. It defines the areas in which the deep n-well diffusions have to take place.

Although the processing steps are somewhatcomplex and depend on the fabrication line. 1 illustrates the major steps involved in a typical p-well CMOS process. The mask that is used in each process step is shown in addition to a sample cross-section through an n-device and a pdevice.

The simplified process sequence for the fabrication of CMOS integrated circuits on a p- type silicon substrate is shown in Fig. The process starts with the creation of the n-well regions for pMOS transistors by impurity implantation into the substrate. Then a thick oxide is grown in the regions surrounding the nMOS and pMOS active regions.

The thin gate oxide is subsequently grown on the.