Flame holders cause a pocket of stagnated burning flow which helps to ignite the fuel-air mixture The combustion chamber is long enough to allow most of the combustion to happen inside such that radiated heat from the burning gas ignites the fuel-air mixture upstream. For the development of a fuel flexible low-emission and reliable combustion system a better understanding of the flow field flame interaction and the flame stabilization mechanism is necessary.

Normally instability will occur before the lean or rich fuelair ratio limit is reached.

Flame stabilization in combustion chamber. Flame stabilization techniques vary by engine type but typically have a bluff body to impart a recirculation zone of hot combustion gases around the fuel injectors and compressed air inlet to prevent flameout. The fuel is not premixed with the combustion air so similar tradeoffs of NOx versus soot emissions occur as in CI. In a mixing and flame stabilization appliance in a combustion chamber with premixed combustion a gaseous andor liquid fuel is introduced into the combustion air.

The combustion air is guided via. Flame holders cause a pocket of stagnated burning flow which helps to ignite the fuel-air mixture The combustion chamber is long enough to allow most of the combustion to happen inside such that radiated heat from the burning gas ignites the fuel-air mixture upstream. For the development of a fuel flexible low-emission and reliable combustion system a better understanding of the flow field flame interaction and the flame stabilization mechanism is necessary.

For this purpose a down-scaled staged can combustion system provided with an optical combustion chamber was investigated in a high pressure test rig. A device and a method for flame stabilization in a burner 10 includes a burner housing at least partially enclosing a burner volume into which may be introduced via at least one fuel line fuel and via at least one air feed means air forming an airfuel mixture spreading in a preferred flow direction which may be ignited in a combustion chamber 11 connecting downstream of the. Lean premixed combustion systems have been used to lower flame temperatures and to avoid stoichiometry non-uniformities that arise due to incomplete mixing of fuel and air.

The goal is to limit peak flame temperatures below a value where thermal NOx production is. Abstract The paper presents a study for conditions for hydrogen self-ignition and flame spreading in a supersonic combustion chamber at the Mach number for the inlet flow equal to 4. The experimental model is a rectangular channel with a flame stabilizer performed as a.

Stability Limit Combustion Chamber Performance. For any combustion the flame will be stable depending on fuelair ratio quality. Flame may blow out at lean fuelair or at rich fuelair mixture.

This is taken as limit of stability in which flame will hold. Normally instability will occur before the lean or rich fuelair ratio limit is reached. FLAME STABILIZATION AND PROPAGATION IN HIGH VELOCITY GAS STREAMS By G.

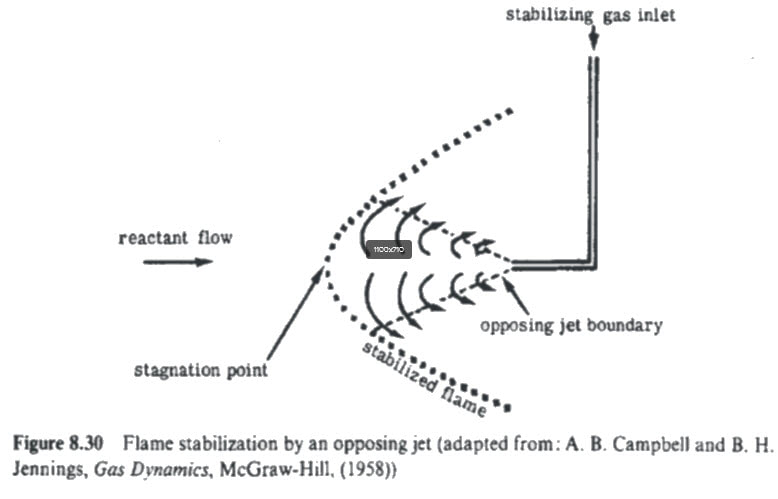

SCURLOCK Parameters on the basis of which high-output combustion chamber performance is evaluated in- clude the air-fuel ratio range over which a stabi- lized flame can be maintained the completeness of combustion the friction pressure. Flame stabilization is usually accomplished by causing some of the combustion products to recirculate and hence to continually ignite the fuel mixture. The hot recirculating gases transfer heat to the colder ones ignite those and initiate flame spread.

The burnt gases transfer heat to the. Abstract The results are presented of the experimental and computational studies of the flame stabilization behind a swirler in an open flow and in a model compartment of the combustion chamber. Using the thermal theory the calculation model of the flame stabilization in the combustion chamber is developed.

The wall of the combustor is flush without any reward step or cavity so the strut-jet is used to make sure of the flame stabilization of the second combustion. Mass flow rate of the kerosene and oxygen injected into the rocket is set to be a small value below 10 of the total fuel when the equivalence ratio of the second combustion is 1. The necessity for stabilizing a flame in a high speed flow of combustible gas has led to extensive studies of the mechanism of flame stabilization by bluff bodies.

One of the major challenges facing designers of low NOx emission combustion systems is flame stability as the weaker combustion process is more vulnerable. Secondly the flame in the combustion chamber cannot survive if the air has a high velocity. So combustion chambers benefit from diffusers to slow down the air flow.

There are two normal kinds of flame stabilizers. Bluff-body flame holders and swirlers. Flame to traverse the combustion chamber is halved in milliseconds.

Double the original speed and half the original time give the same number of crank degrees for flame propagation-The crank angle required for the flame propagation which is main phase of combustion will remain almost constant at all speeds.