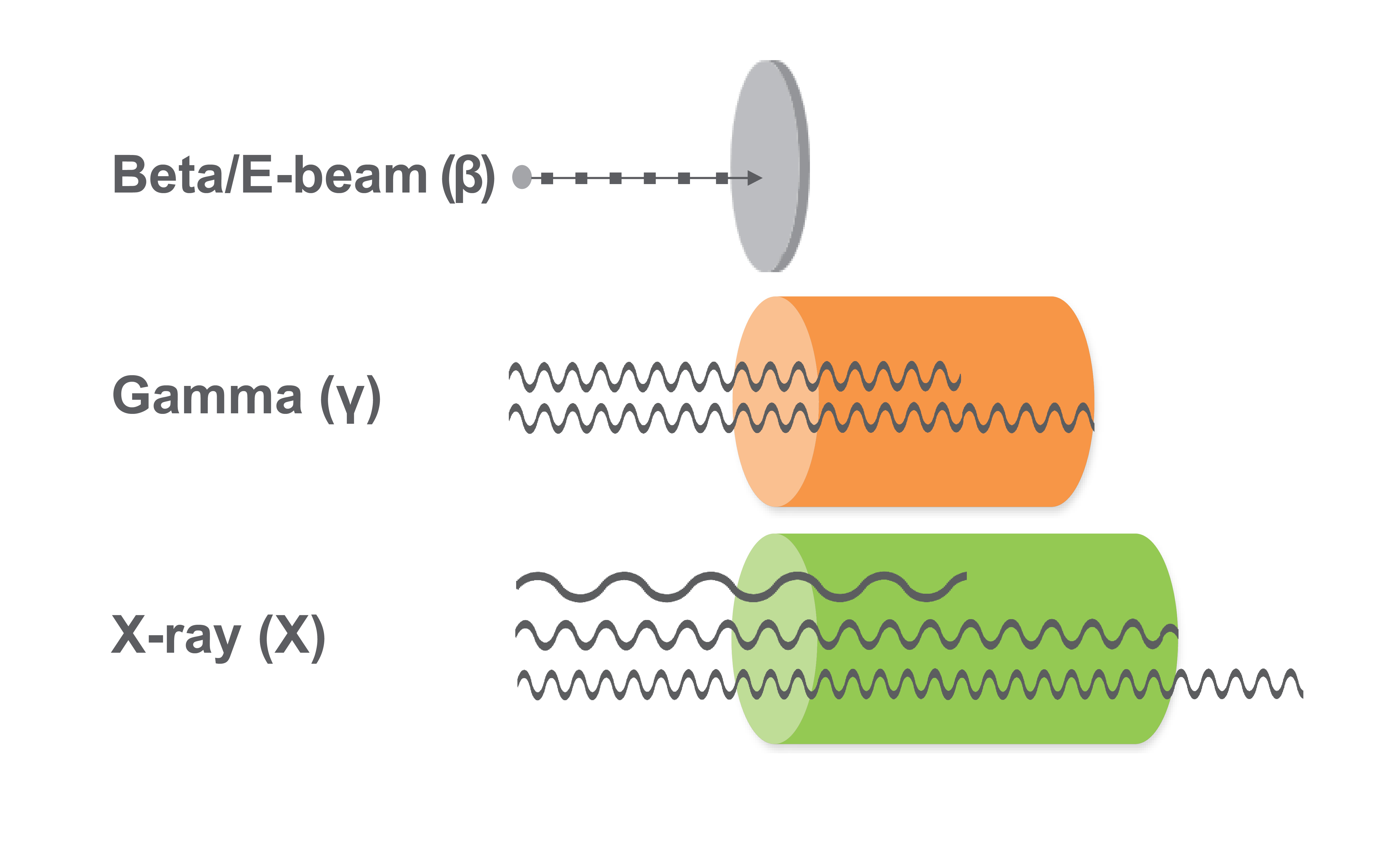

In food irradiation ionizing radiation uses electricity x-rays and gamma rays to destroy microorganisms such as bacteria viruses or insects in food. Irradiation of meat is accomplished by exposing meat to high-energy ionizing radiation produced either by electron accelerators or Read More.

Sterilization and disinfection is commonly by means of warmth chemicals steam low temperature utilization lack of hydration drying up lyophilization adjustment.

Food sterilization by irradiation. Irradiation sterilization is a kind of nuclear technology that uses the physical chemical and biological effects produced by the interaction between ionizing radiation and substances to sterilize materials and materials. Classification of food irradiation equipment. Irradiation has become a standard process used to sterilize many consumer and medical products from adhesive strips to surgical implants.

Three different technologies that can be used to treat food have been developed by the sterilization industry. Irradiation or radurization is a pasteurization method accomplished by exposing meat to doses of radiation. Radurization is as effective as heat pasteurization in killing food-spoilage microorganisms.

Irradiation of meat is accomplished by exposing meat to high-energy ionizing radiation produced either by electron accelerators or Read More. Comparable to canned foods. High levels of irradiation have already been approved for foods for NASAs Space Program and for immune-compromised hospital patients.

Uses of Food Irradiation Irradiation can be used to sterilize eliminate all microorganisms food products at levels above 10 kGy. In the range of 1-10 kGy it can be used to. Using low dose Gamma irradiation STERIS Applied Sterilization Technologies AST is able to safely and effectively control both pathogenic micro-organisms and insects and pests in food for human consumption.

Control of Pathogenic Microorganisms. Food sterilization can be utilized successfully to fight molds and different microbes in spices and herbs. Sterilization and disinfection is commonly by means of warmth chemicals steam low temperature utilization lack of hydration drying up lyophilization adjustment.

The Company owns and operates an irradiation facility located in Mulberry Florida that uses gamma radiation produced by Cobalt 60 to treat or process various food and non-food items for insect disinfestations shelf life extension and reduction of microorganisms. Operations commenced in January 1992 upon completion of its facility. Food irradiation is the process of exposing boxes or pallets of food products to radiation from a Cobalt-60 source.

The ionizing radiation destroys dangerous contaminates in foods such as bacteria viruses fungi and insects. The process is not new. Its been around for the past 60 years.

However as the worlds food supply continues to globalize with new and exotic fruits and vegetables being introduced to foreign. High dose irradiation to produce sterile foods such as ready meals for special medical diets emergency or space diets. These foods are irradiated by doses of 45 kGy to render the foods microbiologically sterile.

The irradiation is carried out under frozen conditions to minimise adverse sensory effects. Irradiation of food that contains unsaturated fats generates peroxide which oxidize and polymerize lipids into non-digestible polymers which as insoluble plaques make. The major method in use for radiation sterilization is gamma irradiation.

Gamma radiation is used in the sterilization of. Disposables such as plastic syringes infusion sets catgut sutures catheters gloves and adhesive dressings before use. Bone tissue grafts antibiotics and hormones.

In food irradiation ionizing radiation uses electricity x-rays and gamma rays to destroy microorganisms such as bacteria viruses or insects in food. Irradiation also delays ripening improves rehydration increases juice yield and inhibits sprouting which helps preserve foods andor keeps them at their peak. The sterilization of low-acid foods pH greater than 46 is generally carried out in steam vessels called retorts at temperatures ranging from 116 to 129 C 240 to 265 F.

The retorts are controlled by automatic devices and detailed records are kept of the time and temperature treatments for. Food Irradiation involves shining electromagnetic radiation like X-rays and gamma rays or electron beams onto food to maintain food quality kill harmful bac.