The government understood that large scale implementation of this technology could help the country achieve CO2 reduction goals. The two main differences be-tween fuel cells and Stirling engines are the significantly higher electrical efficiency ie lower heat-to-power ratio and the higher electric capacity of fuel cell systems when compared to Stirling micro-CHPs 1.

Fuel Cell micro-Cogeneration Fuel Cell micro-Cogeneration also knowns as Stationary Fuel Cells Fuel Cells micro-CHP Fuel Cells Micro-Combined Heat and Power is a technology that uses a single fuel hydrogen natural gas or LPG to produce both heat and electricity for a building.

Household fuel cell cogeneration system. PROBLEM TO BE SOLVED. To enhance thermal durability of components in apparatuses of a fuel cell cogeneration system and to provide the apparatuses wherein the components can be easily maintained. A reforming device 2 is provided in a central lower part in a housing 1 a humidifier 3 is provided in the upper part of the reforming device 2 a fuel cell 4 a cooling water tank.

The worlds smallest high-efficiency household fuel cell cogeneration system ENE-FARM MINI was jointly developed and commercialized. Dainichi Kogyo Co Ltd Kyocera Co Ltd. Tokyo Gas Co Ltd.

Have jointly developed Fuel Cell Unit with a Built-in hot water storage tank called the ENE-FARM MINI the worlds smallest size household fuel cell cogeneration system. In the case of household fuel cell cogeneration the generated electricity is used for electric appliances the heat generated at cogeneration is used for hot water supply and heating. Our household cogeneration generates electricity from city gas and LP gas and extracts electricity and heat.

The fuel cell cogeneration system enables decentralised electricity generation and heat at the consumers home so energy is generated efficiently without transmission loss in the grid. Therefore ENE-FARM is a highly efficient and environment-friendly product. The concept of ENE-FARM is to create energy for your home by.

A fuel cell is based on a reverse reaction of water electrolysis. Hydrogen reacts with oxygen in the air to produce water. In this process electricity and heat are generated.

It is a power generation system that does not produce greenhouse gases like CO 2 in the process of power generation. Fuel Cell micro-Cogeneration Fuel Cell micro-Cogeneration also knowns as Stationary Fuel Cells Fuel Cells micro-CHP Fuel Cells Micro-Combined Heat and Power is a technology that uses a single fuel hydrogen natural gas or LPG to produce both heat and electricity for a building. BlueGEN is a micro CHP system combined heat and power based on fuel cell technology and optimised for maximum use and benefit of electricity to supply small businesses private households or public buildings with highly efficient power and heat.

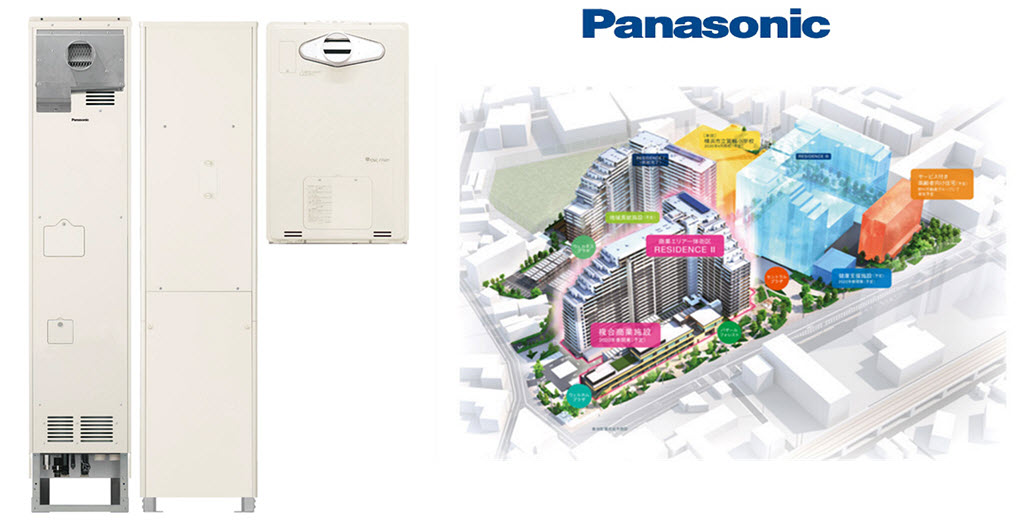

The system supplies around 13000 kWh kilowatt hours of low-emission electricity per year and thus. Household Fuel Cell Cogeneration System Panasonic FuelCellUnit FC1004ARS HotWaterStrageUnit WT4204ARS2AW6QU DomainCategory Product Design - Housing exterior products Company Matsushita Electric Industrial Co Ltd. Japan Award Number 05A06089 Outline of Good Design Award winners Outline of Good Design Award winners 2005.

Since the SOFC cogeneration system has a high proportion of power generation efficiency in total efficiency it offers environmental and economical advantages in household use where there is comparatively small thermal demand. The system was also downsized to improve ease of installation so that more people can use the cogeneration system at home. This household fuel cell cogeneration system simultaneously generates electricity and hot water from city-supplied gas.

As concerns over diminishing fuel resources and global warming rise this system offers a solution to the need for abundant clean power generated in an environmentally sensitive manner. It is also a solution consumers can participate in. First off you will need a supply of Hydrogen to fuel your Fuel Cell.

Depending on your goal you can get this in several different ways. Tube trailers cylinders etc on-site generated eg. Delivered This is pretty straight forward.

Residential cogeneration systems that use polymer electrolyte fuel cells PEFCs have been released and systems that use solid oxide fuel cells SOFCs are being developed. An SOFC in comparison to a PEFC has a high electricity generating efficiency and. Cogeneration system SOFCCGS was developed to collect and use the heat loss.

The heat dissipation generated from SOFC is collected by residential SOFCCGS and supplied to a hot water tank for hot water demand of a household. A fuel cell as a clean energy system. Technology fuel cells are a second promising conversion technology for micro-CHP.

The two main differences be-tween fuel cells and Stirling engines are the significantly higher electrical efficiency ie lower heat-to-power ratio and the higher electric capacity of fuel cell systems when compared to Stirling micro-CHPs 1. Due to these inherently. 2 depicts a simplified configuration of a residential FC-CHP system.

A fuel cell stack produces both electricity and heat from hydrogen produced through city gas reforming. If a households electricity demand is greater than the output of the fuel cell the. One of the main conclusions of the project was that an average Japanese household could prevent 12 tonnes of CO2 emissions each year with a Fuel Cell micro-Cogeneration unit.

The government understood that large scale implementation of this technology could help the country achieve CO2 reduction goals. Which factor made Fuel Cell micro-Cogeneration such a success in Japan.