In a closed system the fluid is not exposed to a break in the piping system that interrupts forced flow at any point. Calculate the total head and select the pump Total head is given by formula 1.

For the meaning of the variables see the nomenclature in table 20.

Pump head calculation closed loop system. The pump head calculation depends on the type of system that the pump serves. In a closed system the fluid is not exposed to a break in the piping system that interrupts forced flow at any point. In an open system it is.

In a closed system the fluid travels through a continuous closed piping system that starts and ends in the same place— there is no break in the piping loop. The vast majority of hydronic. For a chilled water system that is closed loop the supply goes out from the pump through the supply branches which feed different cooling coils and then all feed back to the return branch and back to the pump when I am calculating the pressure drop to get the head for the pump do I total the loss for each branch or only the worst case branch.

One of the unique aspects of closed loop piping systems is that the static elevation is not accounted for in head-pressure calculations as these systems are largely unaffected by static pressure. However just like open flow systems we still need to make checks for sufficient NPSHa that the static pressure throughout the system does not fall below the fluid vapor pressure and therefore induce. A typical heat exchanger closed loop could be similar to this.

Pump-Heat Exchanger-Glycol Chiller makeup water-back to pump. Or if you had a short grade level open loop cooling tower with exchange to a closed loop for pumping to high equipment. Calculate the total head and select the pump Total head is given by formula 1.

For the meaning of the variables see the nomenclature in table 20. If you would like to know more about how this equation was derived see J. Chaurettes book Pump System Analysis and Centrifugal Pump.

While calculating the pump head in a closed loop chilled water system you consider 1 the height of the building in our case the 150 m as static pressure. 2 dynamic head the system losses chillersthusetc. Friction Head Feet Discharge PSI - Inlet PSI x 144 density of fluid in lbs.

Per cubic foot Here is an example for a pressurized closed loop system and pure water at 180 degrees weight 6057 lbs per cubic ft with circulator discharge pressure 155 PSI and circulator inlet pressure 12 PSI. Pump Head-Capacity Indiscussing fluid flow the term Head is frequently used. Pump head refers to the energy contentper unit weightthat a pump is capable oftransferring to the liquid.

The units are usually metrea inthe metric system. Notice from Figure 11 and 12 thatthe pumphead-capacitycurve droops withincreasing capacity. Head varies depending on flow rate but in this case since there is no flow and hence no friction the head of the pump is THE MAXIMUM HEIGHT THAT THE FLUID CAN BE LIFTED TO WITH RESPECT TO THE SURFACE OF THE SUCTION TANK.

Since there is no flow the head also called total head that the pump produces is equal to the static head. In a closed loop system the pump discharge head is never selected on the basis of the building height but on the total system pressure loss. However the Net Positive Suction Head Required NPSHR is also an important pump characteristic to keep in mind when selecting and placing the circulation pump.

Pump Head Calculation - HVAC Chilled Water SystemDownload LinksChilled Water Pipe Sizing and Design CalculationhttpsyoutubemGbz7ygqyX0How to calculate. Pipe length friction losses fitting friction losses hieght difference highest point elevation - lowest point elevation operating pressure of the fixture unite. Closed loop calculation.

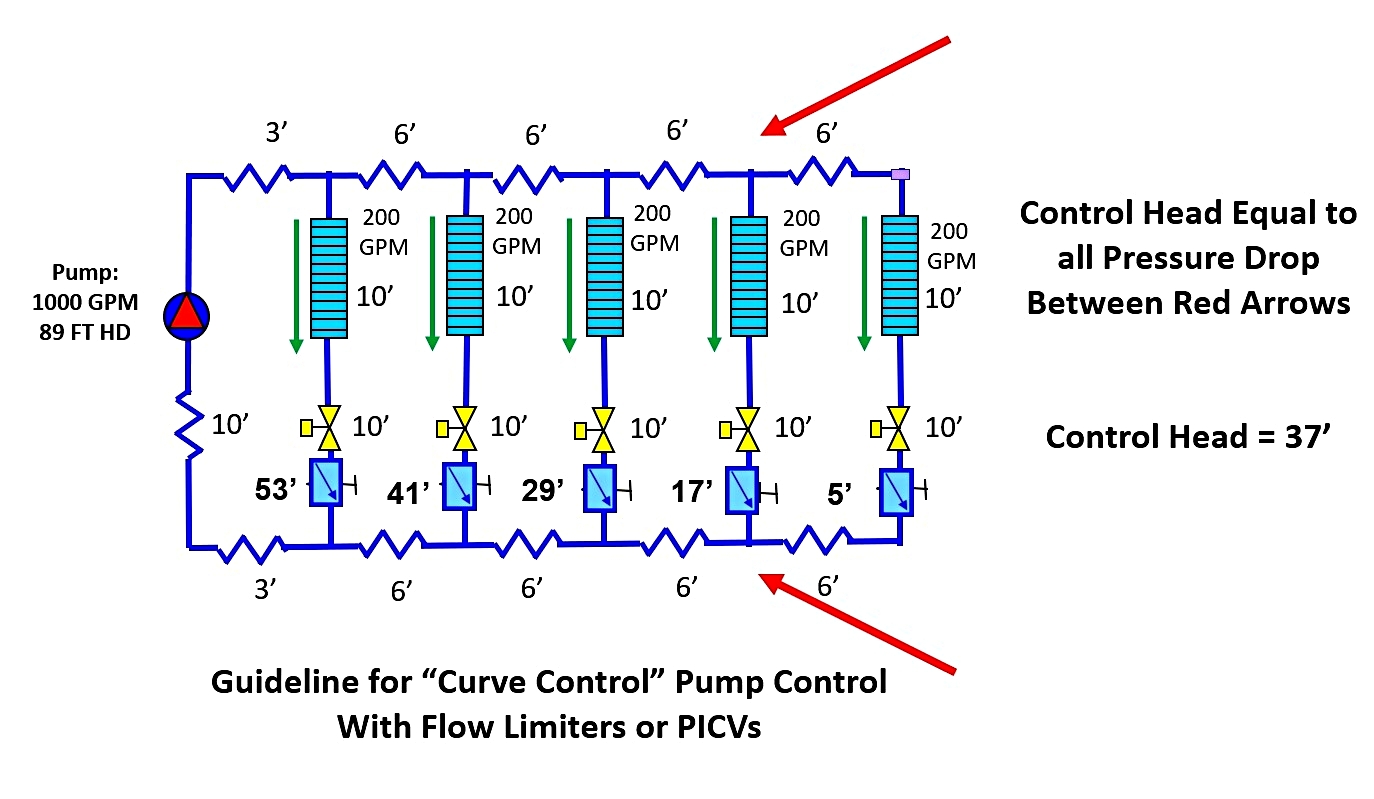

Pipe length friction losses fitting frictional losses pressure drop of farthest equipment FCU or AHU Practically there are two ways to find out. In a multi-loop system typical of HVAC and other distributed service installations each loop typically contains all three of the piping system elements. Pump process and control.

The head loss from the process and control elements in each of these loops is equal to the pump head added by the pump elements. Pump is connected to these include the static head and the dynamic head of the system. The static head is created by any vertical columns of liquid attached to the pump and any pressurized systems attached to the pump outlet.

The static head exists under static conditions with the pump switched off and does 3 not change based on flow. The height of fluid above the pumps centerline can be. Total Dynamic Head in an industrial pumping system is the total amount of pressure when water is flowing in a system.

It is comprised of two parts. The vertical rise and friction loss. It is important to calculate this accurately in order to determine the correct sizing and scale of pumping.

Mechanical energy provided to the fluid Closed loop mechanical energy in hydrostatic load Fluid on open circuit - degraded Energy Power at the shaft of the pump Pumps head Pumps horsepower Pumps Net Positive Suction Head. This video gives a brief overview of the basic function of a chilled water system and Pump Head Calculation basics and explain working of primary pump and s. For optimal pumping it is essential before selecting the pump to have examined the pipe system very carefully as well as the liquid to be conveyed.

Pipe systems have always special characterstics and must be closely inspected for the choice of the appropriate pump. Details as to considerations of pipe systems are given in Chapter 6 Design of. GPM will be known as per the flow distribution and respective pipe sizes.

If 2-12 pipe has head loss of 2440 ft100ft 28 feet will have 07feet of head loss. Calculation to be continued on.