This includes top drives in every size and configuration to meet any drilling application whether marine desert jungle or arctic environments. Drilling A device that turns the drillstringIt consists of one or more motors electric or hydraulic connected with appropriate gearing to a short section of pipe called a quill that in turn may be screwed into a saver sub or the drillstring itself.

Most drilling experts rightly point out that power swivels have always been around and are.

Top drive drilling system. The top drive drilling system is powered by an AC motor. The system is often controlled by a separate control panel. The market of top drive is geographically separated according to the demand criteria.

It can be segmented into Asia Pacific Europe North. 14 rânduri Building upon this legacy of experience in electric top drive systems NOV continues to produce. The two major advantages of a top-drive drilling rig are.

The ability to handle multiple joints two or three joints of drill pipe at one time during connectingunconnecting. The ability to rotate the drill pipe while tripping into or out of the wellbore to avoid Stuck Pipe during tripping. Top Drive Drilling SystemTDS TDS doesnt used the drill pipe which does not limit the length of the pipe so it avoid to connection the drill pipe when drilling 9M.

TDS have ability to drilling 28M the drilling tools can be smoothly raised and rotated without increasing the drilling time especially in the directional drilling process. A Top Drive is an essential piece of drilling equipment. It is basically a large motor system which is hoisted in a derrick mast or drilling rig.

Top Drives can be used in a variety of rigs including truck-mounted rigs and offshore rigs. A top drive is capable of drilling with three joints stands instead of just one pipe at a time. Top drives typically decrease the frequency of stuck pipe which contributes to cost savings.

Top drives reduce risk and increase safety while drilling in several ways. First a top drive allows the driller to quickly engage and disengage pumps or the rotary while removing or restringing the pipe. Typically the frequency of pipe getting stuck is significantly reduced when using top drives thereby resulting in cost savings.

Engineered portable and fixed top drive systems for most land and offshore rigs. This includes top drives in every size and configuration to meet any drilling application whether marine desert jungle or arctic environments. Canrig top drives are engineered and manufactured to API 8-C standards and carry the API monogram setting.

Drilling A device that turns the drillstringIt consists of one or more motors electric or hydraulic connected with appropriate gearing to a short section of pipe called a quill that in turn may be screwed into a saver sub or the drillstring itself. The topdrive is suspended from the hook so the rotary mechanism is free to travel up and down the derrick. With experienced management and staff Topdrive Drillers is committed to providing a safe environmentally conscious service to their valued clients.

Topdrive Drillers can undertake PQ HQ and NQ drilling also offer services in mud rotary large diameter coring and wedging or directional work. For demanding drilling applications. Cameron provides a range of AC-driven top drive systems for demanding drilling applications both onshore and offshore.

All our top drives are supplied with several accessories that have been tailor-made to meet rig requirements. Modularity to reduce maintenance and downtime. Canrig Top Drive Drilling System Overview Top Drive Torque Guide TDSU Service Loops Hydraulic Theory Force Area Pressure Fluids Usage Transmits Power Lubricates Seals Cools Properties Prevent rust corrosion and pitting Prevent the formation of sludge gum varnish Depress foaming.

Top drive systems have brought drilling technology to a whole new level due to the reduction in the number of human-operated process steps when adding a drill pipe length using thurible stands. In this case a kelly joint that mechanically connects the swivel and the rotary table is not needed. Top drives have transformed the drilling industry.

With top drives rigs are safer and more efficient now. Moreover the technology in modern times allows us to reach drilling targets that were once considered unreachable. To help you achieve maximum efficiency we will get you the best quote for Top Drives.

A top-drive drilling system is most often regarded as nothing more than a power swivel that works. Most drilling experts rightly point out that power swivels have always been around and are. IBOP for top drive can be divided into Upper IBOP and Lower IBOP they are control valves which are used with the top drive system.

Usually the two valves connected to the top drive drilling device. The IBOP adopts high reliable metal seal. So it can bear high pressure upward and downward.

The working pressure can be achieved 10000 psi or 15000. Top Drive adalah suatu peralatan yang digunakan untuk memutar pipa pengeboran dalam dunia pengeboran minyak. Berdasarkan sistem kerjanya Top Drive terbagi menjadi dua sistem.

Top Drive Hydraulic System. Top Drive tipe ini Drilling Motor dan seluruh fungsi kerja lainnya Link TiltIBOPRotating AdapterStan Jumpdll digerkan Oleh Hydraulic. A bracket and tension rod device is mounted to a top-drive dolly to carry the weight of a sheave wheel assembly.

The device is deployed by connecting the sheave wheel assembly to a rigid dolly arm with an adjustable tension rod to relieve a gooseneck from adverse tensile compressive and bending forces from the movement of a wireline through the sheave assembly. The Drillmec Electric Top Drive is designed as transportable as well as permanent installed unit for deep drilling rigs with different mast types. The System is powered by an AC motor.

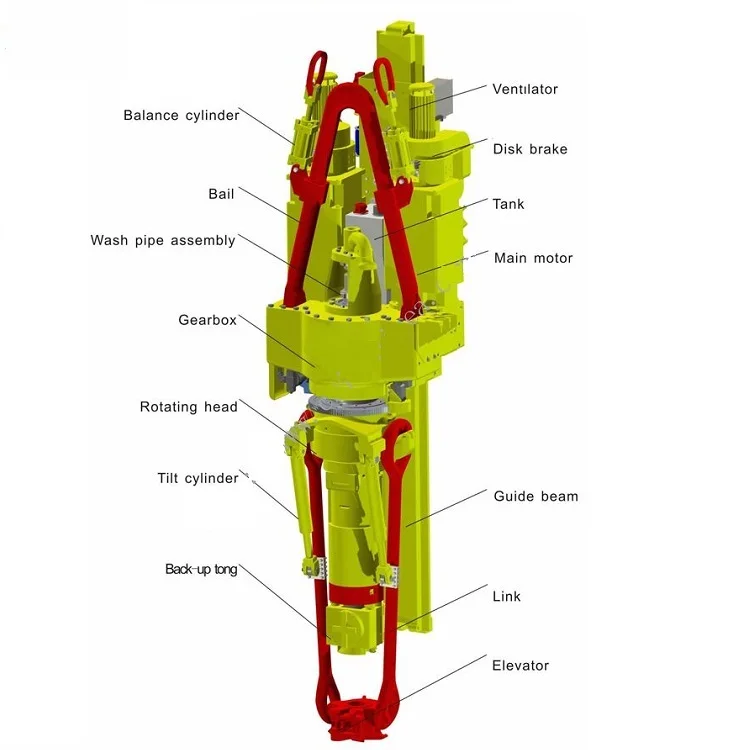

The ETD Series is controlled by a separate control panel. The standard Top Drive version includes the following items.