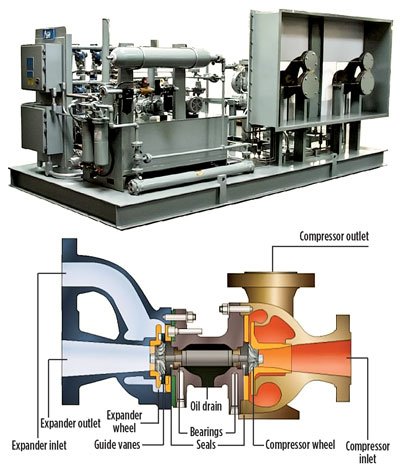

The device has a shaft carried in a housing on bearings with a compressor wheel on one side and an expander wheel on the other side. Worn expander back wheel seal.

English term or phrase.

Turbo expander seal gas system. A turboexpander compressor for use in a gas processing system has a seal system that avoids communication of gas with the oil being pumped through the bearings. The device has a shaft carried in a housing on bearings with a compressor wheel on one side and an expander wheel on the other side. Labyrinth seals seal the wheels from the interior of the housing and the bearings.

Worn expander back wheel seal. With a worn back wheel seal high-pressure process gas can leak behind the expander wheel at rates higher than can be relieved through the expander thrust holes. This can lead to an increase in expander back wheel pressure and high thrust toward the expander.

Instrumentation and control systems seal gas and lube oil systems all coordinated by a project manager in conjunction with the quality department fully involved at each step of the project. Example of configuration of Cryostar Turbo-Expander. A turboexpander compressor for use in a gas processing system has a seal system that avoids communication of gas with the oil being pumped through the bearings.

The device has a shaft carried in a housing on bearings with a compressor wheel on one side and an expander wheel on the other side. Dry Gas Seals. Dry Gas Seals allow the lowest seal gas consumptions but require very high gas cleanliness.

They can be proposed in several configu-rations. Single dual or tandem. The Oil Seals may be used on applications where Dry Gas Seals are too sensitive for the operating conditions.

Lube oil system and that there is no high speed rotating shaft seal needed to prevent leakage of the process gas or oil to the atmos-phere. In applications where there must be a high speed rotating shaft seal such as expander generator systems that do not have the generator rotor immersed in the process fluid then the shaft seal is. A turboexpander is designed to extract energy from a process gas.

High-pressure gas enters the expander case passes through the expander nozzles where it is directed into the expander impeller and then exits through the expander discharge at a lower pressure and temperature. By using turbo-expanders on natural gas distribution systems even if the power obtainable at individual locations is not large compared to the conventional thermal power plants the sum of all locations can be substantial. Turbo-expander evaluation of potential in.

High pressure moderately cold gas flows into the Expander section of the Turboexpander. The gas flows through the Expander Variable Inlet Nozzles Guide Vanes and then through the Wheel exhausting at a lower pressure and at a substantially colder temperature. Gas flows from the Expander to the Demethanizer where condensate is removed.

The first edition of API 692 Dry Gas Sealing Systems for Axial Centrifugal Rotary Screw Compressors and Expanders was released in June 2018. This new standard covers the minimum dry gas sealing system requirements in association with compressors and expanders for use in the petroleum chemical and gas industry services. Turbine End Sealing System.

At the turbine end the sealing system is simple. After the oil has finished its work in the bearings it travels along the shaft until it reaches the hub where the spinning oil thrower literally throws the oil outwards by centrifugal force and it meets the inside face of the center housing where it drops down under gravity to be collected by the oil drain and. Gas Expander Gas Expander Turboden gas expander is a solution to enhance the energy efficiency of a natural gas network infrastructure producing electricity by taking advantage of the reduction of gas pressure from the delivery level to the one required by users be they residential or industrial.

In this video we will describe How Compressor Gas Seal System Work and compression sealdry gas sealgas sealdry sealcompressor dry gas seallabyrinth seal. A turbo-expander or expansion turbine is a radial in-flow or centrifugal turbine capable of efficient extraction of energy from any high-pressure gas being expanded through it. Turbo-expanders are typically used to provide industrial refrigeration like in the cryogenic treatment of natural gas to extract ethane butane and propane or to.

Ses by recovering gas at a high pressures. Dry gas seals are also available. Patented automatic thrust balancing system Our system allows the unit to reliably handle high thrust loads associated with high-pressure applications including at start-up shut-down and process upset conditions.

High efficiency gas dynamic turbo-expander and com. Shaft sealing and Dry gas Seal Labyrinth type using seal gas to prevent cold gas migration into bearing housing and prevent oil leakage into the process stream The seal gas typically a warm process gas The supply pressure should be minimum 50 PSID above expander. Cryogenic chilling in the PETROGAS Model TE System utilizes a TURBO EXPANDER that replaces the Joule-Thompson expansion valve in a conventional refrigeration system.

The expansion valve is adiabatic as well as a turbine and taking the work out of the expansion makes it isentropic. English term or phrase. Turbo expander seal gas system the housing held a filter for a turbo expander seal gas system a the clients facility in New-Orleans M A P Local time.

Système de gaz de barrage pour turbodétendeur. The seal gas gaz de barrage is used to pressurize the sealing device it may be a mechanical seal.