In each case assume that the specimen begins at 800 C and that it has been held at this. Using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition figure 1022 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small specimen that has been subjected to the following timetemperature treatments.

1018 using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition figure 1022 specify the nature of the final microstructure in terms of.

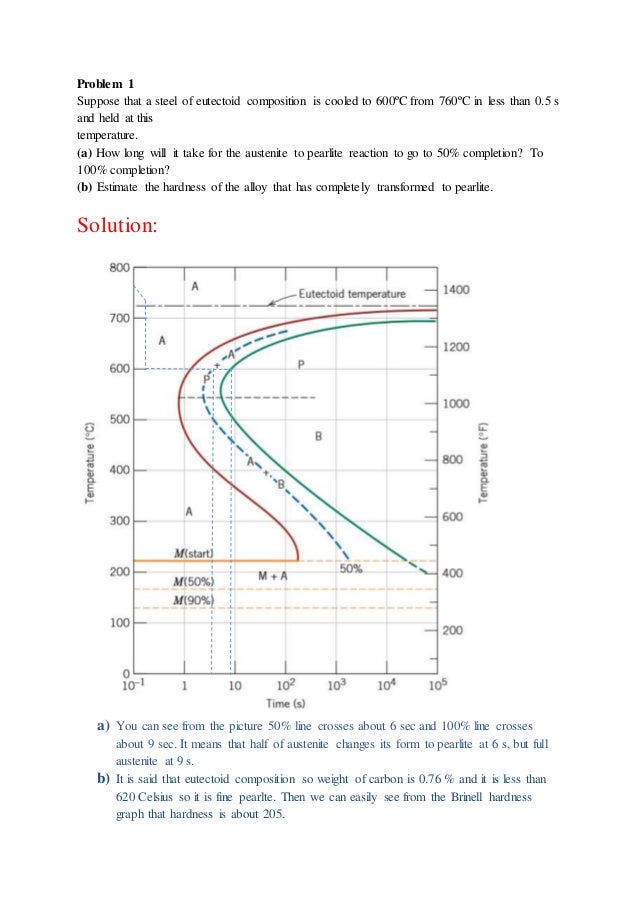

Using the isothermal transformation diagram for an iron carbon. Using The Isothermal Transformation Diagram For An Ironcarbon Alloy Of Eutectoid Composition. The higher the temperature the thicker the layers. A from figure 1022 a horizontal line at 550 c intersects the 50 and reaction completion curves at about 25 and 6 seconds respectively.

Using The Isothermal Transformation Diagram For An Ironcarbon Alloy Of Eutectoid Composition. In each case assume that the specimen begins at 760 degree c 1400 degree f and that it has been held at this temperature long enough to have achieved a. Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition Figure 1123 specify the nature of the final mi- crostructure in terms of microconstituents pres- ent and approximate percentages of each of a small specimen that has been subjected to the fol- lowing time-temperature treatments.

Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small specimen that has been subjected to the following time-temperature treatments. In each case assume that the specimen begins at. Using the isothermal.

Using the isothermal transformation diagram for an ironcarbon alloy of eutectoid compositionFigure 1023 specify the nature of the final microstructure in terms of microconstituents presentand approximate percentages of each of a small specimen that has been subjected to the following time temperature treatments. In each case assume that the specimen begins at 760C 1400F and. 1018 Using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition Figure 1022 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small specimen that has been subjected to the following timetemperature treatments.

Using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition shown in the figure describe the final microstructure constituents present and approximate percentages of each of a small specimen that has been subjected to the. Using the isothermal Transformation Diagram for An Iron-carbon Alloy Of Eutectoid Composition. Solved 10 19 using the isothermal transformation diagram 10 19 using the isothermal transformation diagram for an iron carbon alloy of eutectoid position figure 10 22 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of.

The complete isothermal transformation diagram for an iron carbon alloy of eutectoid composition. The isothermal transformation diagrams are a graph or pictorial representation of the temperature changes with respect to time in the particular alloy composition of. Using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition Figure specify the nature of the final microstructure in terms of micro constituents present and approximate percentages of each of a small specimen that has been subjected to the following timetemperature treatments.

In each case assume that the specimen begins at 760C 1400F. Using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition figure 1022 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small specimen that has been subjected to the following timetemperature treatments. 1018 using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition figure 1022 specify the nature of the final microstructure in terms of.

Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition Figure 1022 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small specimen that has been subjected to the following time-temperature treatments. Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition figure below specify the final microstructure in terms of microconstituents present and approximate percentages of each of a specimen that has been subjected to the following time-temperature treatments 1 to 5. In each case assume that the specimen begins at 760C 1033 K and have achieved a.

Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition Fe-076 wtC specify the final microstructure in terms of microconstituents present and approximate percentages of each for the cases listed below. In each case assume that the specimen begins at 760A degree C and that it has been held at this temperature long enough to have achieved a complete and. Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition specify the nature of the final microstructure in terms of micro-constituents present and approximate percentages of each of a small specimen that has been subjected to the following time- temperature treatments.

Using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition figure 1022 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small specimen that has been subjected to the. Problem 2 Using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition Figure 1022 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small specimen that has been subjected to the following time temperature treatments. In each case assume that the specimen begins at 760ºC and.

69 Make a copy of the isothermal transformation diagram for an ironâcarbon alloy of eutectoid composition Figure 1022 and then sketch and label timeâtemperature paths on this diagram to produce the following microstructures. Using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition Figure 1 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small specimen that has been subjected to the following timetemperature treatments. In each case assume that the specimen begins at 800 C and that it has been held at this.

Using the continuous-cooling transformation diagram for an iron-carbon alloy of eutectoid composition Figure 1028 name the microstructural products of specimens having this eutectoid compositions that are first completely transformed to austenite then cooled to room temperature at the following rates.