C REGENERATIVE OR. It is through this technology that most of the industrial processes are successfully carried out.

B DIRECT CONTACT TYPE HEAT EXCHNAGER.

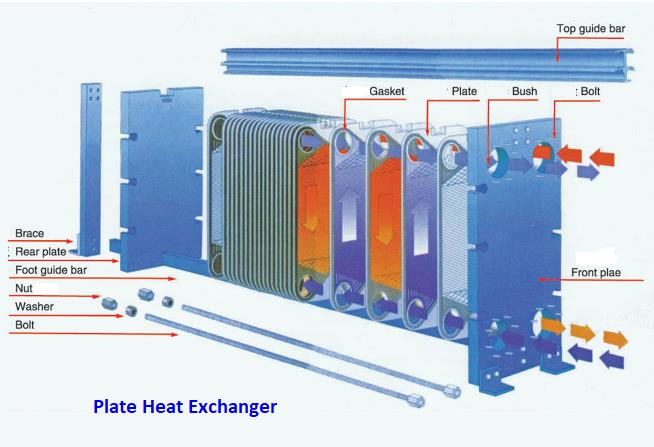

What are the different types of heat exchangers. Heat exchanger types vary to meet requirements for processing efficiency cost of ownership and maintenance. In this blog we describe plate and frame shell and tube and scraped surface heat exchangers used in food beverage dairy and pharmaceutical processing. Plate and frame heat exchanger.

What are the different types of heat exchanger. In the simplest heat exchanger two fluids one cold and one hot move in the same or. The fluids can also flow in perpendicular directions which is known as cross flow arrangement.

In these types of arrangement the cold and hot fluids enter the exchanger at opposite ends and flow in opposite directions as shown in the figure below. Counter flow heat exchanger. The compact heat exchanger.

This type of heat exchanger is designed to allow a. DIFFERENT TYPES OF HEAT EXCHANGER A Direct Transfer type Heat Exchanger. These are also known as recuperators heat exchangers.

In which the fluids are. B DIRECT CONTACT TYPE HEAT EXCHNAGER. In direct contact type heat exchanger both hot fluid and cold fluid physically.

C REGENERATIVE OR. There are four different types of heat exchangers which are detailed below. Adiabatic Wheel Heat Exchanger.

Used to store heat an intermediate fluid is used in this kind of heat exchanger. The fluid transfers heat to the exchanger units opposite side. Types of heat exchangers Shell and tube type The most basic and the most common type of heat exchanger construction is the shell and tube type.

This type of heat exchanger consists of a set of tubes in a container called a shell. This type of heat exchanger also referred to as a surface heat exchanger can be further classified into direct-transfer type storage type and fluidized-bed exchangers. Regenerative heat exchangers are types of heat exchanger equipment that utilizes a heat storage medium that is made to contact with the hot and cold fluids.

The two fluids are usually gases. They are used in power plants glass and steel making and heat recovery systems. Generally there are four types of heat exchangers used for heat controlling.

Shell and tube heat exchanger plate heat exchanger tubular heat exchanger and fin type heat exchanger. Theory behind heat exchanger is applying Heat Transfer. Conduction Convection and Radiation according to the medium of solid or liquid or gas.

Types of Heat Exchangers. What You Must Know Basic Definition. Even as the magnitude and complexity of heat exchangers changes you must keep in mind that their.

Due to these many classifications we will choose one of them and run away with it. In the industry we. Shell and Tube Heat Exchangers.

Out of all the types of heat exchangers shell and tube heat exchangers are the most versatile. A shell and tube heat exchanger is designed with a number of tubes placed inside a cylindrical shell. The popular design of this type of heat exchanger allows for a wide range of pressures and temperatures.

This type of heat exchanger also referred to as a surface heat exchanger can be further classified into direct-transfer type storage type and fluidized-bed exchangers. The heat exchanger is an important component in every large industry. It is through this technology that most of the industrial processes are successfully carried out.

The basic principle of its use is to transfer heat whether in liquid or gas form through a series of conductive channels. Heat convection refers to heat transfer that occurs between a surface and a moving fluid which are different temperatures. Convection heat transfer is subdivided into two different kinds according to the nature of the flow.

Forced convection occurs when the flow is caused by an external force such as a pump or a fan. There are many types of permanently bonded plate heat exchangers such as dip-brazed vacuum-brazed and welded plate varieties and they are often specified for closed-loop applications such as refrigeration. Plate heat exchangers also differ in the types of plates that are used and in the configurations of those plates.

Broadly grouped the three major types of heat exchangers are. Shell and tube plate and frame and tube and tube.