The difference lies in your objective or desired outcome. Blanking is a metal fabricating process during which a metal workpiece is removed from the primary metal strip or sheet when it is punched.

The blanking process is the most suitable process to manufacture the component from aluminum alloy and resin transfer molding RTM to manufacture the component in composite materials.

What is blanking in manufacturing. Precision blanking is a fabrication process that uses a punch and die to remove a pieceie a blankfrom a sheet or strip of material. Both the punch and die are in the shape of the desired component ensuring the piece removed has the. Blanking is a metal fabricating process during which a metal workpiece is removed from the primary metal strip or sheet when it is punched.

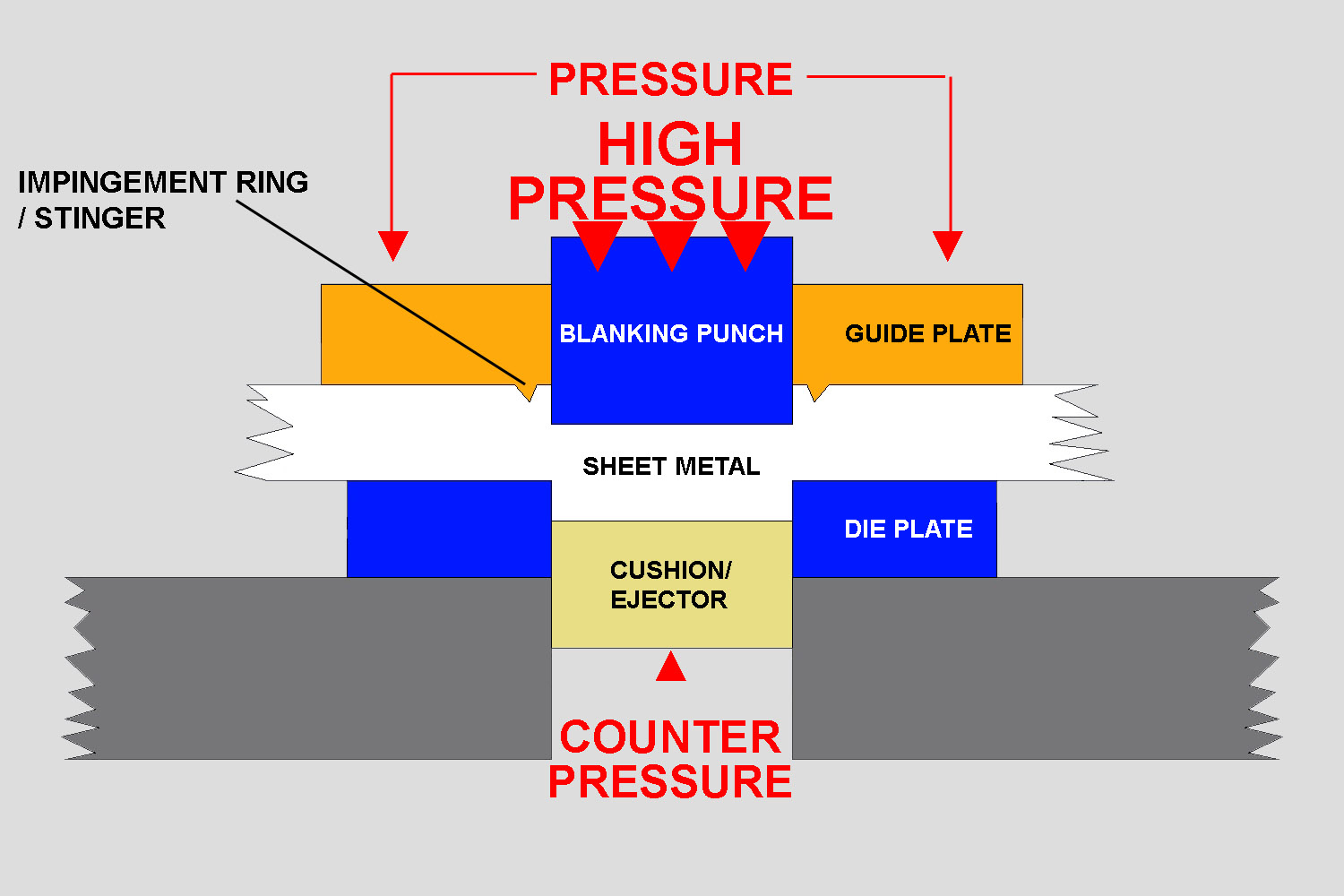

The material that is removed is the new metal workpiece or blank. Characteristics of the blanking process include. As shown in below image The blanking is a sheet metal cutting process that is used to manufacture an enclosed sheet metal part from a large piece of sheet metal by the application of high shear force.

As a result of the blanking process the blank part is a finished product. Blanking process is cutting process obtain in sheet metal in which sheet metal piece is removed from the large piece of stock by shearing force applied in the sheet metal. When the blanking of sheet metal process the removal of piece is called as blank.

The technology of fine blanking parts mainly refers to ensure the technical and usage requirements of the parts and it should be the simplest and most economical in manufacturing under certain batch production conditions. The main factors affecting it are. 1 Technology in the construction of parts.

Punching and blanking are technically the same operation in which you cut out shear a piece of desired shape and size from a sheet metal. The difference lies in your objective or desired outcome. In Blanking the cut out part is the desired product and the remaining sheet with the void is discarded.

Punching and blanking processes are sheet metal forming processes. In these two processes a finite volume of metal from a sheet is removed by using die and punch. The shape and size of the portion removed depends on the geometry of die and punch.

Also the operation cost and time depends on die and punch design. In blanking operations the final part or product is removed or punched-out out of the larger sheet material with the remaining material being discarded as scrap. On the other hand in punching operations the material removed is discarded and the final product is the remaining material which then undergoes further processing.

The blanking process is the most suitable process to manufacture the component from aluminum alloy and resin transfer molding RTM to manufacture the component in composite materials. Based on a process-based cost model the costs of these processes were computed considering the. A blanking die produces a flat piece of material by cutting the desired shape in one operation.

The finished part is referred to as a blank. Generally a blanking die may only cut the outside contour of a part often used for parts with no internal features. Three benefits to die blanking are.

Chemical blanking is an alternative to stamping coining punching laser water jet or wire EDM for producing the initial stage of a fabricated metal component. As an alternative to stamping or coining the tooling costs for chemical blanking are minimal generally under 300 USD. With blanking the metal from the hole is saved and used rather than discarded.

In other words manufacturing companies perform blanking to create small pieces of metal whereas manufacturing companies perform piercing to create metal objects with a single hole. Fine blanking also known as fine-edge blanking is a special type of stamping process that produces parts of enhanced accuracy flatness and edge characteristics. 6-1 METAL-CUTTING PROCESS Metal cutting is a process used for separating a piece of material of predetermined shape and size from the remaining portion of a strip or sheet of metal.

Learn more about Chapter 6. Blanking and Piercing Operations on GlobalSpec.