Another purpose of homogenization is to smash the cell wall or cell membrane or both and the intracellular contents will be exposed. Prevents cream formation.

Supplying a constant and controlled back-pressure to the first stage giving best possible conditions for homogenization Breaking up clusters formed directly after homogenization as shown in Figure 633.

What is the purpose of homogenising stage. The purpose of homogenization is to reduce the particle sizes that make up the biological sample render them easier for molecular extraction. Another purpose of homogenization is to smash the cell wall or cell membrane or both and the intracellular contents will be exposed. The aim of the homogenisation process is to effectively and efficiently disrupt and break the cells outer membrane thereby releasing their subcellular components nuclei mitochondria.

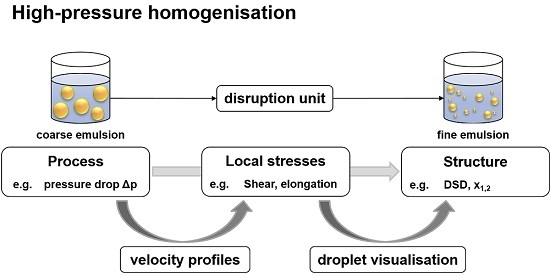

Homogenization or homogenisation is any of several processes used to make a mixture of two mutually non-soluble liquids the same throughout. This is achieved by turning one of the liquids into a state consisting of extremely small particles distributed uniformly throughout the other liquid. A typical example is the homogenization of milk where the milk fat globules are reduced in size and dispersed.

Two stage homogenization is usually preferred for ice cream mix. Clumping or clustering of the fat is reduced thereby producing a thinner more rapidly whipped mix. Melt-down is also improved.

Homogenization provides the following functions in ice cream manufacture. Reduces size of fat globules. Areobtained when the relation P2P1 is about 02.

The second stage also reduces noise and vibrations in the outlet pipe Bylund 2003. Single-stage homogenization may be used for homogenization of products with high fat content demanding a high viscosity certain cluster formation. Two-stage homogenization is used primarily to reach optimal.

The second stage basically serves two purposes. Supplying a constant and controlled back-pressure to the first stage giving best possible conditions for homogenization Breaking up clusters formed directly after homogenization as shown in Figure 633. Homogenization of milk also serves the following purposes.

Prevents cream formation. Increases milk viscosity it gives richer appearance to tea or coffee. Fat globules do not rise readily and there is no necessity for agitating the milk before serving.

Prevents churning of fat during rough handling or excessive agitation. The homogenate in first filtered to remove unbroken cell clumps and collected in a centrifuge tube. The filtered homogenate when centrifuged in a series of steps at successively greater speeds each step yields a pellet and a supernatant The supernant of each step is removed to a fresh tube for centrifugation.

The purpose of homogenization is to create a stable emulsion where the fat globules dont rise to form a cream layer. How it works When homogenizing milk you feed high quantities of the product through a really small gap between two pieces of steel called a homogenizing device at high velocity. During this stage air is incorporated to produce a foam.

Liquid fat is released from globules at the surfaces of air bubbles and this binds together clumps of solid fat to form butter grains. These are then mixed or worked at low speed to disperse water as fine droplets throughout the mass of butter and to rupture any fat globules remaining from the cream. Although butter is thought of as a wo emulsion.

Homogenising effect upon many customs practices and institutions. In business life it led among other things to a desire to harmonise Accounting Standards among countries. Our purpose is to answer the question.

What is the international harmonisation process of Accounting Standards what is its status quo and how important is the. What is the purpose of the homogenising stage in DNA extraction What is the function of isopropanol in DNA extraction. The purpose of homogenization is to reduce the particle sizes that make up the.

PRO Scientific rotor stator homogenizers outperform cutting blade-type blenders and are well suited for plant and animal tissue homogenization. PRO Homogenizers are mechanical high shear homogenizers for blending mixing disrupting emulsifying dispersing and stirring. PRO Scientific Homogenizers include rotor-stator homogenizers and blade type homogenizers.

Cultural homogenization is understood as a state-led policy aimed at cultural standardization and the overlap between state and culture. Homogeneity however is an ideological construct presupposing the existence of a unified organic community. It does not describe an actual phenomenon.

Genocide and ethnic cleansing meanwhile can be described as a form of social engineering and. Homogenisers are used mainly for the purpose of providing stable fat-in-water emulsions so that the fat in the milk base does not separate but homogenisation also brings about some desirable physical changes in the milk base which contribute towards. Whiter and more attractive colour of the milk improved mouthfeel of the product.

The purpose of homogenizing is to produce a mixture which is as homogeneous as possible ie. Has an extremely even consistency from phases which are difficult to mix or cannot form a solution. In the petrochemical chemical and pharmaceutical industries homogenizing plays a key role in producing products of constantly high quality.